Engineered For High Volume Collection Operations!

The DL3 high capacity grapple loader does more volume! Introducing the model DL3, nicknamed “The Twister”. Engineered for high volume collection operations after hurricanes, ice storms, or tornadoes. Operated by dual mechanical joystick controls located at the stationary top-mount seat. The DL3 is great for disaster cleanup, but is also versatile enough that you can use it for your regular bulky trash and brush collection routes that need a larger body size.

Petersen Industries DL3 High Capacity Grapple Loader Advantages

Efficient

- Dump 2x the Legal Payload

- Lift 7,100 pounds and dump up to 72,000 pounds

- Faster than chipping and less invasive than a wheel loader

- Single operator turn-key system

- Great tool for hauling land clearing or site prep debris

Maximum Capacity

- Customized to Your Needs

- Choose our Heavy Duty body or upgrade to a Hardox® body, both in 40 or 45 cubic yard sizeDuty cycle rated and proven

- Stationary top-mount mechanical joystick controls

- 40-45 cubic yard trash dump body

- ANSI Z245 Compliant

Top Seat

Because of the proportional joysticks, the foot pedal swing, and an oversized seat designed for maximum comfort, you could stay up here all day long.

Hydraulic System

Experience the most precise and efficient execution in the industry. Our variable speed pump gives you control where you want it, when you want it, without slowing down.

Slewing System/Gearbox

Steady as she goes.

Our stabilizing swing circuit ensures smooth starts and stops, reducing the overall stress on the boom and slewing system. After three seconds of inactivity, the integral break locks down the boom which eliminates the need for a mechanical swing lock.

H-Style Outriggers

Horizontal and vertical outriggers act independently of each other, allowing the operator to have incredible accuracy in maneuvering around obstructions and traffic patterns. Not only does this provide a wider base than an A-frame system, the vertical outrigger leg is the ideal position for our heavy duty strobe light.

Big Bite Bucket

We’ve skinned this larger bucket in Hardox 450 so you can use the full force of the cylinders without worrying about tearing a hole in your bucket. With simple hose routing and brake washers on both axes, this is the easiest and smoothest operating two cylinder bucket you’ll find.

General

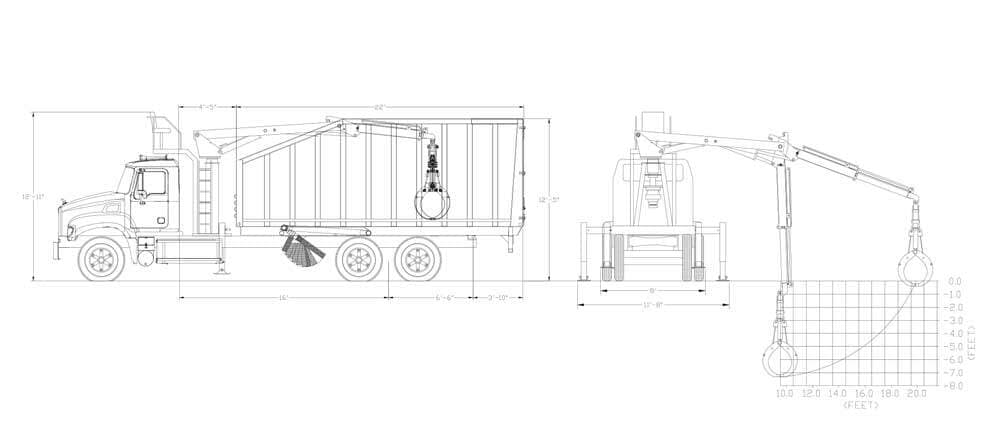

| Reach (from centerline rotation) | 20 feet |

| Main Boom and Tip 800m | 16 feet |

| Tip Extension | 4 feet |

| Tare Weight (empty) | 36,660 lbs |

| Front Axle Weight | 10,860 lbs |

| Rear Axle Weight | 25,800 lbs |

| Outrigger Span | 11′ 8″ |

| Storage Height | 12′ 5″ |

| Dump Body Hoist Capacity | 35 tons |

| Overall Height | 12′ 4″ |

| Tandem Pump |

Lifting Capacity

10 Foot Radius - 7,100 lbs

16 Foot Radius - 4,400 lbs

20 Foot Radius - 3,200 lbs

Weight of bucket and or attachments must be subtracted from lift capacities shown. Standard bucket weighs appx. 1000 lbs. Capacities shown do not exceed 85% of vehicle tipping moment with outriggers fully extended on firm, level ground.

Bucket Features

All purpose clamshell design, 4 feet wide with an opened width of 5 feet. Replaceable bolt-on bucket blades made of high impact tempered steel. Anti-scalping bucket sides are pivot mounted to provide a horizontal closing action rather than a vertical digging motion. Sides are mechanically linked to single hydraulic cylinder to ensure both sides close and open together. Continuous rotation. No hoses below bucket rotator.

Sample Chassis Specification

| Body Style | Conventional Cab |

| Cab-to-Trunnion Dimension | 171″ |

| Front Axle Rating | 14,000 lbs |

| Rear Axle Rating | 40,000 lbs |

| Tag Axle Rating | 20,000 lbs |

| Gross Vehicle Weight Rating | 74,000 lbs |

| Frame | 2,500,000 RBM |

| Engine | 340 HP Diesel |

These are not complete chassis specifications. Call your Petersen representative about other possible chassis arrangements and for complete chassis specs.

Trash Body

22 feet, 45 cubic yard capacity is standard size. Solid plate floor on cross members with 12″ centers.

Operator Controls

Operator station is located on a stationary platform above the truck cab to provide good visibility of the loading area and of the inside of the dump body. Two mechanical six function joysticks located on either side of the operator seat control loader operation. Outrigger controls are located to the left of the operator seat. Body dump controls are located inside the chassis cab.

Structural

A-frame pedestal design allows flexing under repeated load shocks. Replaceable Cast Nylon Bushings used in head assembly. Head assembly is stress relieved. Reinforced connection points with hardened pins and replaceable bushings. Counterbalance valves used on all boom cylinders and pilot operated check valves used on vertical outrigger cylinders.